Hotline:

language

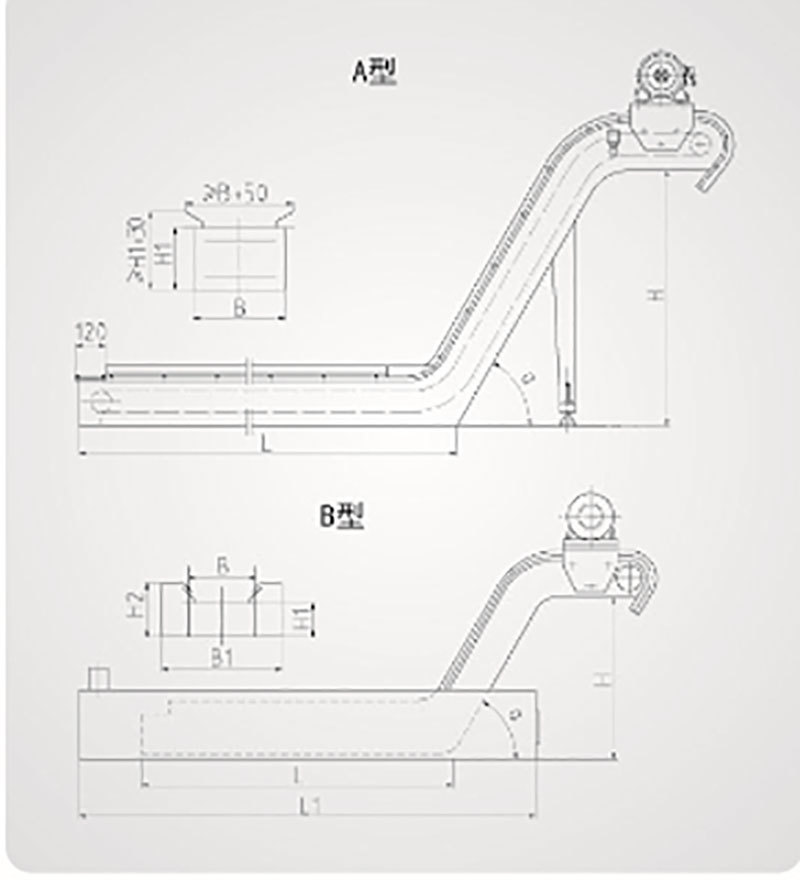

Permanent magnet chip conveyor (CP)

This device utilizes the magnetic force generated by permanent magnetic materials

Classification:

Details

Description

This device uses the magnetic force generated by permanent magnetic materials to adsorb iron filings onto the working panel of the chip conveyor. The magnetic material is driven by a chain inside the housing, conveying the iron filings to a designated chip disposal location or collection box. It can be used to convey powdery, granular, and iron filings less than 100mm in length generated during dry processing, or to separate iron filings (excluding powder) from coolant.

Application Scenarios

It can be widely used in the iron filings conveying of CNC machine tools, combination machine tools, machining centers, gear processing machine tools, drilling, milling, boring, reaming, and broaching, and other mechanical processing equipment and automatic lines. The working panel and the housing are reliably sealed, the operation is stable, the noise is low, the quantitative chip removal does not cause overload, and the service life is long. It can be arbitrarily configured and placed according to the host machine. It can work independently or be linked with the host machine, and it can also be used as a conveying device for small workpieces.

Technical Parameters

Main Technical Parameter Table Unit: mm

|

Model |

B |

B1 |

H(m) |

H1 |

H2、L1 |

L(m) |

α |

Chip Removal Amount (kg/min) |

Motor Power (kw) |

Coolant Pump Flow Rate (L/min) |

|

DCP250 |

250 |

>350 |

0~3.00 |

170、204 |

Customer |

0.60~10.00 |

0° 30° 45° 60° |

100 |

0.2~0.75 |

25 50 100 200 300 |

|

DCP300 |

300 |

>400 |

0~5.00 |

0.60~30.00 |

150 |

0.2~1.5 |

||||

|

DCP350 |

350 |

>450 |

0~10.00 |

200 |

||||||

|

DCP400 |

400 |

>500 |

250 |

0.4~1.5 |

||||||

|

DCP450 |

450 |

>550 |

300 |

|||||||

|

DCP500 |

500 |

>650 |

400 |

|||||||

|

DCP550 |

550 |

>750 |

500 |

Note: Type A has no water tank; Type B is equipped with a water tank. It can also be designed and manufactured according to customer's required size and requirements.

Previous

Previous

Other Products

Product Consulting