Hotline:

language

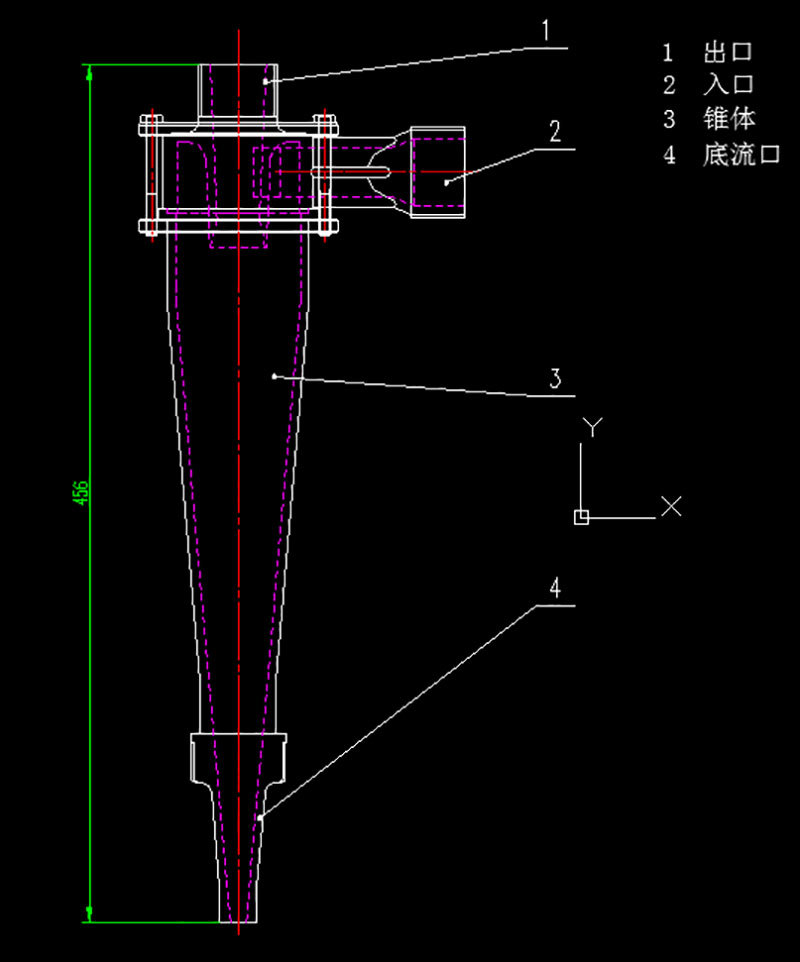

Vortex separator

A vortex separator utilizes a certain pressure to inject a liquid containing particulate

Classification:

Details

Description

The vortex separator utilizes a certain pressure to inject the liquid containing particulate impurities from the inlet at a high speed along the tangential direction into the cone. This creates an outer vortex in the cone, causing the solid particles in the liquid to be thrown towards the inner wall of the cone under the action of centrifugal force. Under the action of gravity and the liquid, the particles are discharged from the bottom outlet along the inner wall. The separated clean liquid reaches the bottom of the cone, and then spirals upwards along the axis of the cone to form an inner vortex, and is discharged from the outlet of the vortex separator. This achieves the separation of dirty liquid and clean liquid with high separation precision; it can separate 98% of particles exceeding 30 μm.

Vortex separators are mainly used for separating tiny particles from liquids. They are suitable for separating particles from coolants used in high-speed grinding, heavy-duty grinding, general fine machining, and low-viscosity oil-based coolants. The cleaned coolant can improve tool life and reliability, improve part processing quality, and prevent coolant deterioration, extending its service life.

Vortex separators can be used in parallel to increase flow rate or in series to improve filtration accuracy.

Precautions: The boost pump pressure should be between 1.5-2.5 bar. Please install a ball valve and pressure gauge at the inlet of the vortex separator to control the coolant pressure.

Technical Parameters

Main Technical Parameters Table

|

Model |

Flow Rate (L/min) |

Boost Pump Flow Rate (L/min) |

Boost Pump Head (m) |

|

DWF70L |

70 |

70 |

15-25 |

|

DWF90L |

90 |

90 |

Previous

Next

Previous

Next

Other Products

Product Consulting