Hotline:

language

Magnetic separator

The precision grinder magnetic separator is used for the purification

Classification:

Details

Description

The precision grinder magnetic separator is used for the purification of grinding machine and other machine tool coolants (cutting oil or emulsified liquid). The magnetic roller of the separator absorbs iron filings in the coolant, keeping the coolant clean. Using a magnetic separator can reduce the number of grinding wheel corrections, improve the surface smoothness of the workpiece, and extend the service life of the grinding wheel and coolant.

In grinding processing, with the improvement of processing precision, high-speed grinding and high-power grinding technology have developed rapidly. In addition to selecting reasonable grinding parameters, it is also necessary to improve the circulation quality of the grinding fluid. Purification devices are divided into two types: filtration type and power type. The filtration type removes impurities by means of a filter medium, such as filter net type, line gap type, plate type and paper belt type filter. The power type separates impurities by means of a certain force (such as centrifugal force, magnetic force or gravity), such as centrifugal type, vortex type and magnetic type separators.

When grinding ferromagnetic materials, the waste liquid contains both ferromagnetic substances and non-ferromagnetic impurities. Generally, a magnetic separator is used to remove more than 80% of the impurities. If better control of filtration accuracy is required, the magnetic separator and paper belt filter are used in combination.

It is a general-purpose separation device. Structurally, it is divided into two forms (I, II).

The I (roller type) series magnetic separator consists of the following parts: reducer, housing, magnetic roller and roller. The reducer drives the magnetic roller to rotate. After the coolant containing powdery magnetic impurities enters the housing, the impurities are adsorbed to the outer wall of the magnetic roller, and then the liquid is squeezed out by the roller, and finally the scraper separates the impurities from the magnetic roller. It is widely used in the purification of cutting fluids containing powdery impurities in such as surface grinders, internal and external cylindrical grinders, and centerless grinders.

The II (comb type) series magnetic separator consists of the following parts: reducer, housing, magnetic roller and scraper. As an improved product of the traditional magnetic separator, the (comb type) magnetic separator has many advantages: the magnetic roller of the same length is made into a comb shape, and the adsorption area is greatly increased; the magnetic force is large, and the separation rate is high; it is especially suitable for centralized separation and removal of large-flow coolants; it can separate granular chips. The II (comb type) series magnetic separator is widely used in: various ordinary grinding machines, powder coating lines, roll grinders, steel rolling wastewater purification, bearing grinding lines and other cutting fluid purification occasions containing granular impurities.

Used for the purification of grinding machine and other machine tool coolants (cutting oil or emulsion), mainly used for the automatic separation of ferromagnetic materials, keeping the cutting fluid clean, improving processing performance and tool life, and reducing environmental pollution. The separator roller uses strong magnetic force to separate ferromagnetic chips and abrasive from the machine tool cutting fluid (oil and water), realizing automatic separation. This improves the quality of processed products, reduces costs, and improves production efficiency.

Applications

It is especially suitable for the purification of coolants in various grinding machines, precision grinding, wire drawing machines, and electrical processing equipment, as well as the purification of coolants in grinding machines and other precision machining machine tools. Most applications are in separating debris. The main market for magnetic separators is the separation of debris in machine tool processing such as lathes, grinders, and planers. It can also be used in the iron selection process of industrial waste and chemical intermediates. With the increasing use of aluminum in the market, the amount of aluminum dross produced is inevitably increasing. If iron is present, it cannot be used reasonably, so a magnetic separator is needed for separation. It is also widely used in the refining of copper powder and non-ferrous metals.

Product Features

1. The transmission system and the housing are separated, making cleaning and maintenance convenient.

2. The magnetic roller is uniformly magnetized, and the separated abrasive and iron powder are dry.

3. It can handle coolants containing powdery magnetic impurities.

4. The large magnetic field generated by the stainless steel magnetic roller has a large adsorption area and good separation effect.

5. Simple appearance, compact structure, stable operation, low noise, and low power consumption.

6. Small size, convenient installation and use, can be designed and manufactured according to the specific space of the machine tool.

Technical Parameters

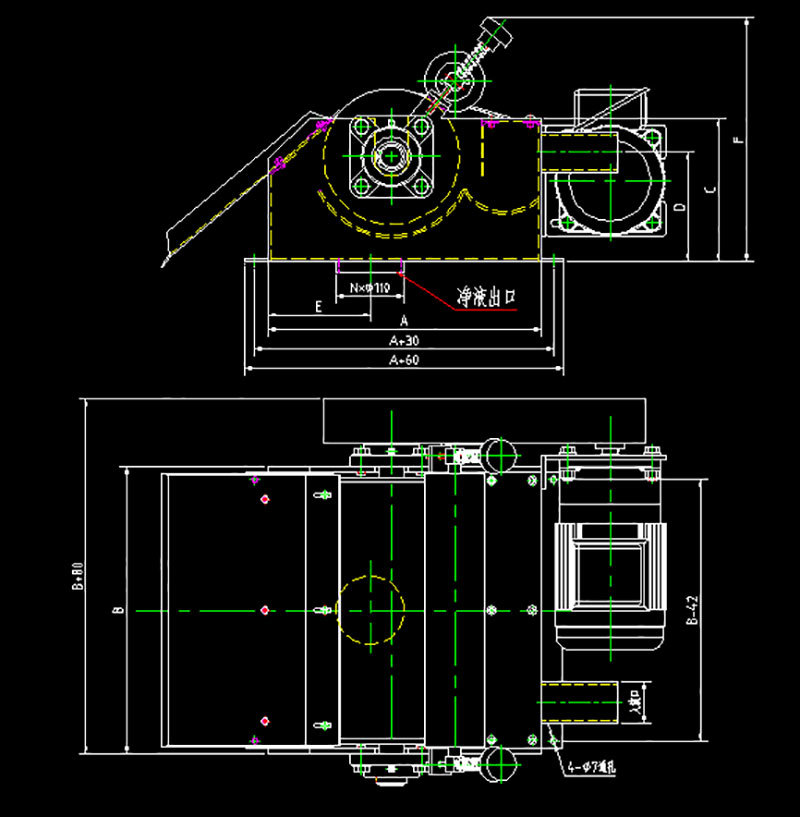

Main Technical Parameters Table Unit: (mm)

|

Model |

A |

B |

C |

D |

E |

F |

ΦD |

N |

Flow Rate |

Magnetic Roller Speed |

Motor Power (kw) |

|

DCF25 |

320 |

276 |

170 |

130 |

120 |

≤350 |

G1 |

1 |

25 |

3 |

0.075 |

|

DCF50 |

336 |

G11/2 |

50 |

||||||||

|

DCF75 |

406 |

75 |

|||||||||

|

DCF100 |

456 |

G2 |

100 |

||||||||

|

DCF150 |

450 |

606 |

2 |

150 |

|||||||

|

DC200 |

656 |

200 |

|||||||||

|

DCF250 |

550 |

706 |

G21/2 |

250 |

|

0.1 |

|||||

|

DCF300 |

756 |

300 |

|||||||||

|

DCF400 |

856 |

G3 |

3 |

400 |

|||||||

|

DCF500 |

956 |

500 |

Note: 1. Please specify the motor assembly direction when ordering;

2. It can be designed and manufactured according to customer's required size and requirements;

3. The above parameters are only applicable to emulsion. Please contact our technical department if it is oil.

Previous

Next

Previous

Next

Other Products

Product Consulting