Hotline:

language

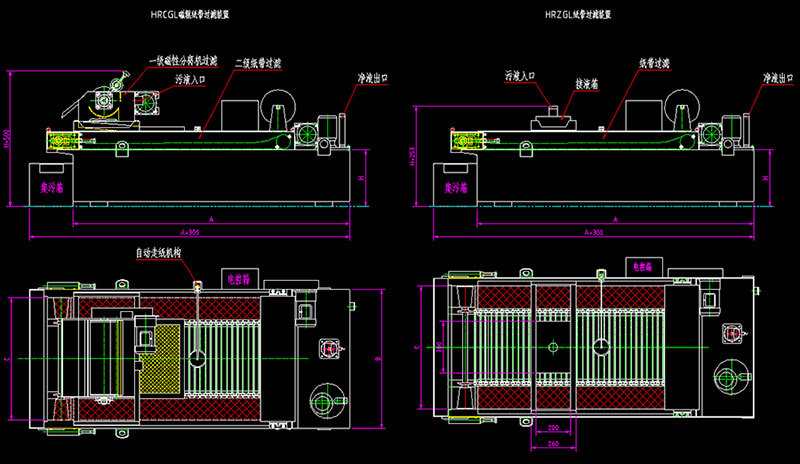

Paper tape filter

Drum belt filter, also known as drum paper belt filter, is a new form of gravity paper belt filter.

Classification:

Details

Description

Drum-type paper belt filter, also known as drum paper belt filter, is a new form of gravity-type paper belt filter. It is a continuous operation, when the filter cake formed by sludge on the filter paper is thick enough to affect the filtration amount, the filter paper switch will start the paper feed motor to output dirty paper and input new filter paper.

Selection must match the machine tool flow and grinding requirements. Currently, drum filters are available in three categories: single-machine matching, matching with magnetic separators, and integrated drum filter systems. Regardless of the type, matching should be based on the site conditions.

1. Gravity-type paper belt filter: This type includes flat-net paper belt filter, arc-net paper belt filter, plate-frame paper belt filter, etc. These all belong to the category of gravity-type paper belt filters. Paper belt filtration relies on the liquid's own gravity to penetrate the filter cloth. This type of filter generally has a filtration capacity of 50L/min-2000L/min, with a filtration accuracy of about 15-20 microns. It has a smaller footprint and is suitable for single-machine filtration, such as cold rolling liquid filtration systems.

2. Forced paper belt filter: This includes negative pressure paper belt filter, positive pressure paper belt filter, Hoffman paper belt filter, etc. This type of filter can achieve a flow rate of 5000L/min, with a filtration accuracy of 10 microns. It features fully automatic filtration, including flushing, oil removal, and oxygenation systems. This filtration method is a recent development trend. For example, a negative pressure integrated filtration system includes scraping, filtration, magnetic separation, oxygenation, oil removal, and paper collection systems.

Product Features

First Feature: High filtration accuracy, generally 25-30 microns.

Second Feature: Good filtration effect, significantly less filter cloth consumables compared to general filters.

Third Feature: High single-machine flow rate and small footprint, allowing for better selection and matching of equipment.

Technical Parameters

Main Technical Parameters Unit: mm

|

Model |

Flow Rate |

A |

B |

C |

H |

Filter Paper Width |

Motor Power (kw) |

Filtration Accuracy (um) |

|

DGL25 |

25 |

920 |

466 |

380 |

≥3000 |

400 |

0.075 |

≤20~25 |

|

DGL50 |

50 |

1200 |

606 |

520 |

520 |

|||

|

DGL75 |

75 |

1600 |

||||||

|

DGL100 |

100 |

806 |

720 |

720 |

||||

|

DGL125 |

125 |

1700 |

1086 |

1000 |

1000 |

|||

|

DGL150 |

150 |

1800 |

||||||

|

DGL200 |

200 |

2200 |

||||||

|

DGL250 |

250 |

2600 |

0.1 |

|||||

|

DGL300 |

300 |

3000 |

||||||

|

DGL400 |

400 |

3400 |

||||||

|

DGL500 |

500 |

3800 |

Note: 1. Please specify the motor installation direction when ordering;

2. We can design and manufacture according to customer's required size and requirements;

3. The above parameters are only applicable to emulsion. For oil, please contact our technical department.

Previous

Next

Previous

Next

Other Products

Product Consulting